28 - 31 October 2025 | Singapore Expo

Blog

Discover trending topics that are propelling the industry

Smarter, faster and greener — machines that create, think and save

Textile manufacturers face constant pressure to produce more with less — less energy, less labour, less waste. The latest technologies combine high productivity with sustainability, giving mills a decisive competitive edge.

Measurable energy savings, increased automation — on and between machines — and tighter digital connections from design to fabric will be highlighted by some of the major providers of spinning, weaving and knitting technologies at ITMA ASIA + CITME, Singapore 2025.

Spinning

In spinning, India’s Lakshmi Machine Works (LMW) is now pushing the length and speed of ring spinning machines with its latest LR 90 series models which can be equipped with up to 2,400 spindles and achieve speeds of up to 30,000 rpm.

LMW is pairing energy-efficient spindles with revised pneumafil and compact suction to achieve 10% overall power savings compared to earlier machines. Quality-package upgrades target up to 30% fewer yarn imperfections while ring frame auto piecing (RAP) uses break detection to dispatch a travelling unit that re-joins at the affected spindle in roughly half a minute, reducing reliance on labour and avoiding human handling of the package.

China’s Jingwei and its group partners are meanwhile now promoting complete lines consisting of the JWF1217 comber, the JWF1590 fine spinning frame and the K3501F twisting system all linked by a full-process logistics concept, with cans, packages and data all moving in smarter ways.

Jingwei’s JWF1580 family is based on 36-spindle modules for mills looking for incremental growth, and focused on easier installation, faster doffing and sensible power trimming.

A full model change of its automatic winder after more than a decade has recently been made by Japan’s Muratec with the introduction of the Alcone. Better linking between ring frame and winder, enhanced self-diagnostics and higher, steadier winding efficiency requiring less operator input are key features.

Switzerland-headquartered Rieter has further drawn together a portfolio of technologies that does more than enhance efficiency. By bringing together intelligent automation, seamless machine networking and advanced process optimisation, the company is enabling spinning mills to take decisive steps towards full transformation.

This portfolio is a milestone on the path to Rieter’s 2027 vision — the fully automated spinning mill. At the heart of this vision is the progressive automation of every stage of production, from bale transport through to can movement and on to final packaging, where steaming, palletising and labelling are all integrated into a single, automated flow.

Weaving

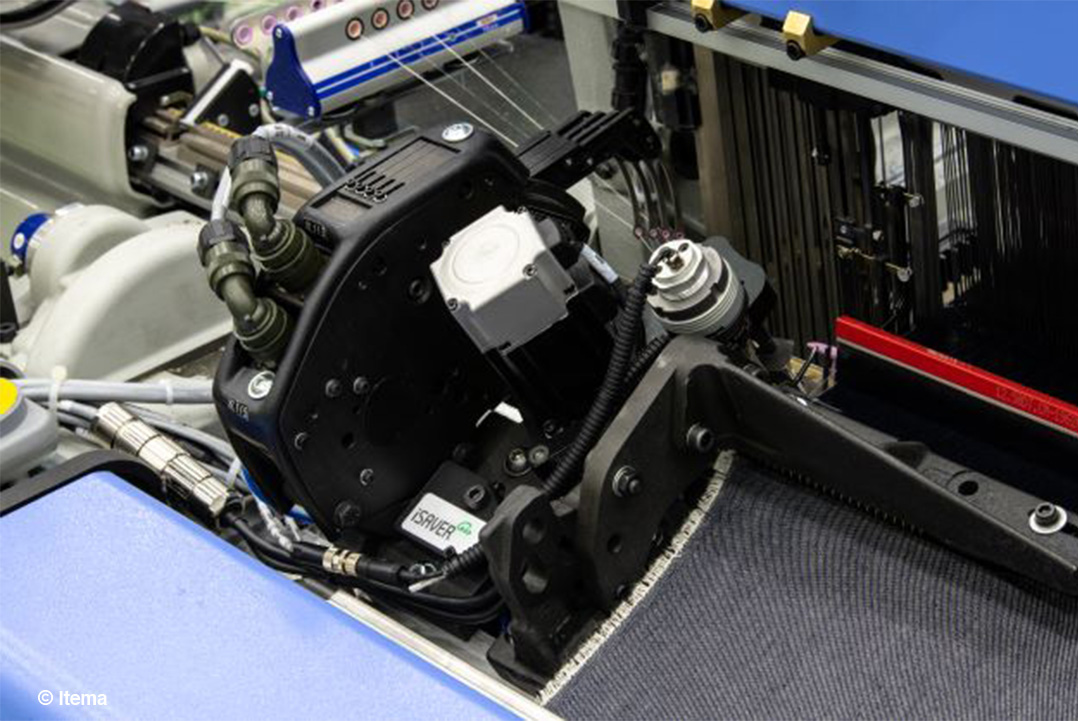

The latest GalileoRX rapier weaving machine, launched in 2022 by Italy’s Itema to address the specific needs of the Asian textile markets, enables mills to reach unbeatable new levels of performance and eco-efficiency and has rapidly gained acceptance for its flexibility and precision.

It benefits from a 15.6-inch-wide full glass capacitive touchscreen display and the iSAVER fancy — a device which eliminates waste selvedge on the left-hand side of the rapier machine, for substantial material and cost savings.

The ZAX001neo air-jet loom developed by Japan’s Tsudakoma meanwhile features redesigned sub-nozzles and an updated weft-insertion set-up to achieve around 35% less air consumption and around 20% lower air pressure than the previous model, while maintaining woven quality, especially on delicate linings. A direct-gear drive in the drive section and a high-efficiency back up the energy claims with mechanical changes rather than just nozzle tweaks.

Data meanwhile fully drives the latest weaving machines of Belgium-headquartered Picanol. Its latest Supermax rapier, via the PicConnect digital platform, provides a wide range of features — from industrial IoT to service-related applications.

Accessed through a web browser on any device, PicConnect enables weavers to quickly react to changes in the weaving room. Intuitive control is the aim, with interactive displays making all operations easy, instinctive and self-explanatory.

Knitting

Shima Seiki’s SWG-XR four-needlebed Wholegarment machine is now in its fifth generation, and the company says lifts productivity by more than 25% compared to the previous platform thanks to a lighter, compact carriage with four systems, a spring-type moveable sinker system and auto yarn carriers. The machine supports a wider variety of yarns for true all-season programmes and adds knitting options like punch-lace and efficient double-knitting.

Shima Seiki has also updated its SDS-ONE APEX4 and APEXFiz design tools to speed 3D programming and make virtual sampling more realistic, bridging design intent and machine data with fewer physical samples.

Germany’s Mayer & Cie is celebrating its 120th anniversary in 2025 and in Singapore will showcase the OVJA 2.4 EC II circular knitting machine which is engineered in Germany and manufactured at the company’s factory in China, predominantly aimed at customers in Southeast Asia.

Thanks to a new system for single needle selection, the machine has a significantly reduced cylinder height and in addition, fewer knitting elements are required, which significantly reduces energy consumption. The OVJA 2.4 EC II produces fabrics for sports and leisure wear and is also being widely used in the field of home textiles, especially in the production of mattress cover fabrics.

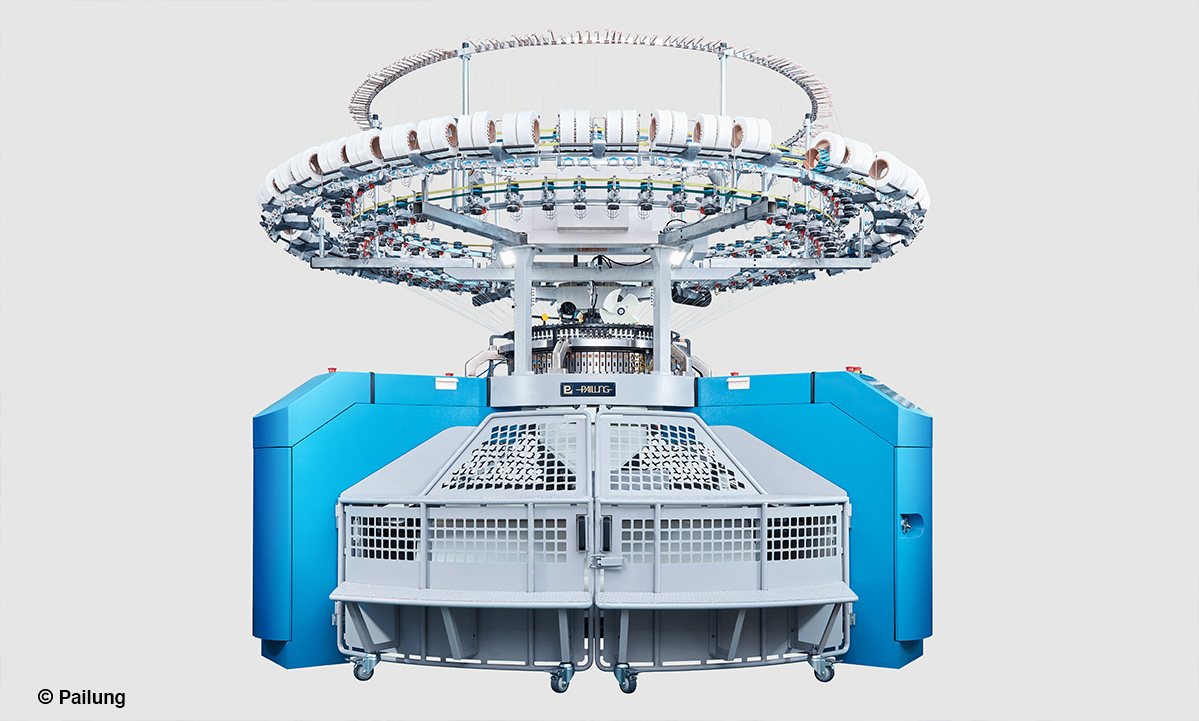

AlterKnit is an upgraded inverse plating technique developed by Taiwan’s Pailung that knits patterns into the structure of a fabric rather than printing or dyeing it on top. It can achieve crisp, reversible motifs with up to four colours per face, including gradients and emblems, in single or double-knit, and without floats to trim.

Because the colour is in the yarn rather than on the surface, there’s an environmental upside and less risk of dye or binder shedding — and a real waste saving in development and production. The company has also leaned into factory-level tools with MES and a fabric defect detection system that pushes circular knitting towards closed-loop quality control rather than after-the-fact inspection.

Precision and creativity

The technologies to be unveiled in Singapore highlight just how far spinning, weaving and knitting have advanced in speed, precision and creativity.

From automated handling to colour-on-demand knitting, these breakthroughs not only improve production — they open entirely new possibilities for fabrics, fashion and performance. Textile and garment makers will appreciate these innovations first-hand at ITMA ASIA + CITME, Singapore 2025.