28 - 31 October 2025 | Singapore Expo

Blog

Discover trending topics that are propelling the industry

No replacement for nimble fingers

As manufacturers increasingly adopt Industry 4.0 principles, it will be very evident at ITMA ASIA + CITME in Singapore this October that automation is impacting almost every aspect of today’s textiles manufacturing sector – from fibre production to fabric formation.

What can’t be automated so successfully, however, is the dexterity of skilled human fingers to accurately manipulate materials through sewing machines.

Designing and creating garment patterns, as the starting point for the entire garment making process, has in the past also required skilled designers who are not only highly creative, but also adept at handling often complex CAD tools.

Garment design though, is now undergoing a transformation, with traditional methods being significantly replaced by digital tools, AI and 3D modelling, which offer greater simplicity, efficiency and precision.

Nesting and cutting

In garment parts assembly too, CAD systems now enable fully automatic pattern drafting, grading, nesting and part cutting.

Multi-ply cutting solutions for both just-in time and mass production processes can fulfil last-minute orders with little need for manual intervention and minimal cost per cut part is the result, regardless of the production volume.

Given that fabric is the biggest production expense for fashion brands (around 60-70% of costs) and that making a single garment can generate up to 20% waste, optimised nesting – the process of marking and laying out cutting patterns on fabrics – also plays a critical role.

This is something that is still done manually by skilled workers in many mills throughout the world, but advanced programs can now automatically calculate the ideal distribution of cutting patterns, analysing the parts to be produced for each cutting job and using algorithms to determine how to lay them out to best produce the required quantities, while minimising the amount of space between the patterns.

3D pattern-making software platforms are also accelerating digital fabric sourcing prior to 3D design and production and also eliminating previously time-consuming and costly fabric sampling.

Bunching and stretching

Unlike steel, plastic and other rigid parts that have enabled the full automation of other industries, however, fabrics bunch and stretch and their properties can vary significantly in how they respond to being sewn together.

Seamless knitting machines can eliminate seams altogether and hence potentially avoid this sewing bottleneck, but while the technologies have been highly successful for high-end, premium products, the time it takes to manufacture a single garment is still much longer than simply cutting individual fabric components and manually sewing them together.

As a result, the various stages of garment manufacturing – from pattern making through to quality control and packaging – involve more people at nearly every stage compared to fabric production.

Sewing remains the most labour-intensive of all production stages, and depending on the complexity of the garments being produced, typically involves between 30-50% of the total workforce of a mill that is vertically integrated from yarn spinning through to finished garments.

It should not be forgotten that the final assembly of garments from their various components secures regular work for millions of people, often in regions where other job opportunities can be limited – and especially women.

One-stop shopping

ITMA ASIA + CITME, Singapore 2025 will offer garment manufacturers a comprehensive range of solutions, from smart pattern-making systems to advanced brand labels.

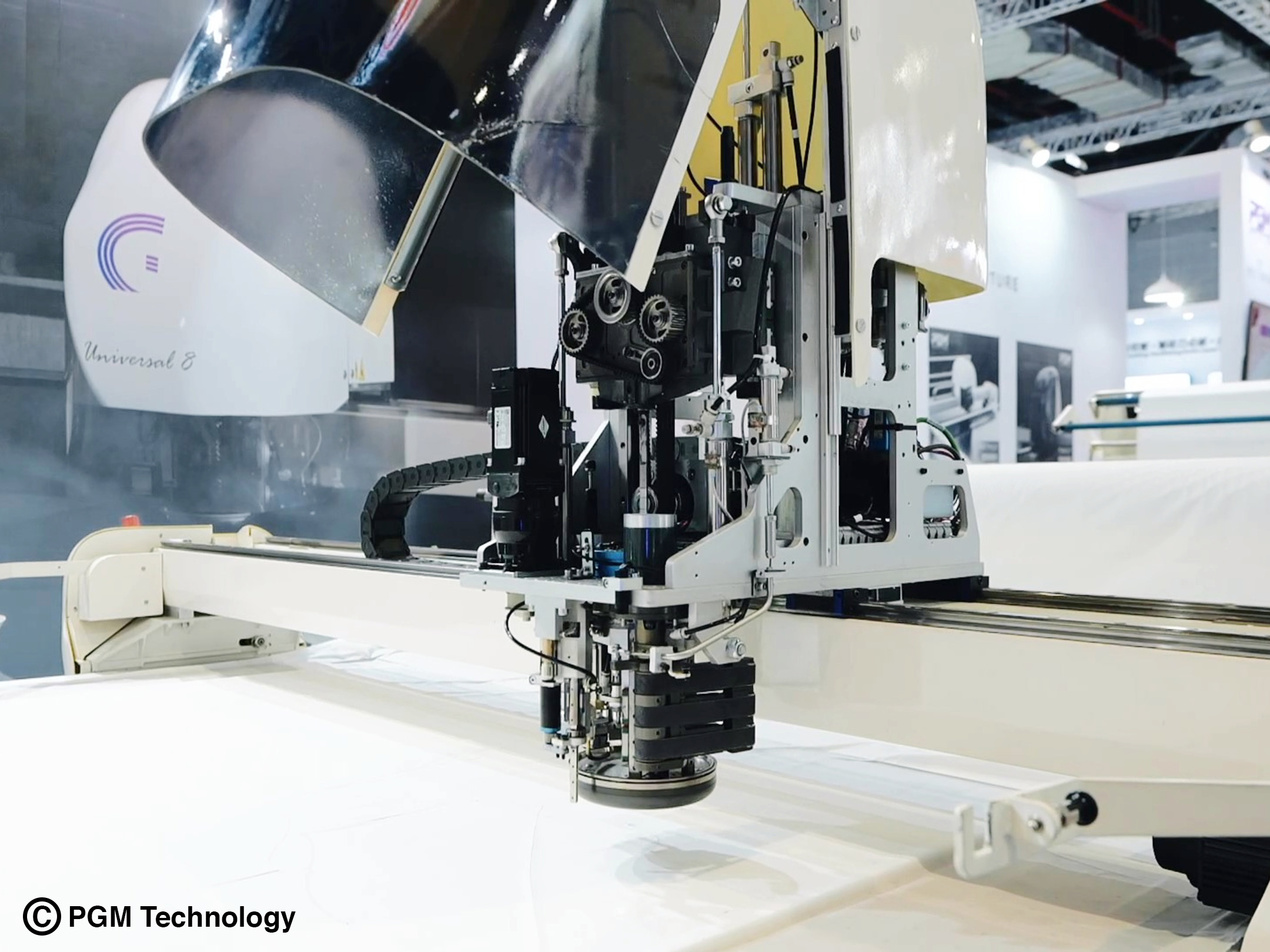

Shanghai-based PGM Technology, for example, will showcase its advanced AI-integrated solutions for pattern-making and cutting, along with highly efficient fabric spreading and laying machines.

Singapore’s Focus Garment Tech will be introducing its own range of sewing machines, together with an array of garment equipment that ranges from automated knitting machines to thread trimmer and heat transfer machines.

Digital ID technology providing garment manufacturers and retailers with real-time insights on every aspect of their supply chains is also becoming increasingly important. Among exhibitors in this field, Avery Dennison will showcase its labelling solutions, radio frequency identification (RFID) inlays and tags, along with traceability software connecting the physical and digital to provide branded packaging and display critical information that is of equal importance to both supply chain partners and the end consumer.

Home textiles

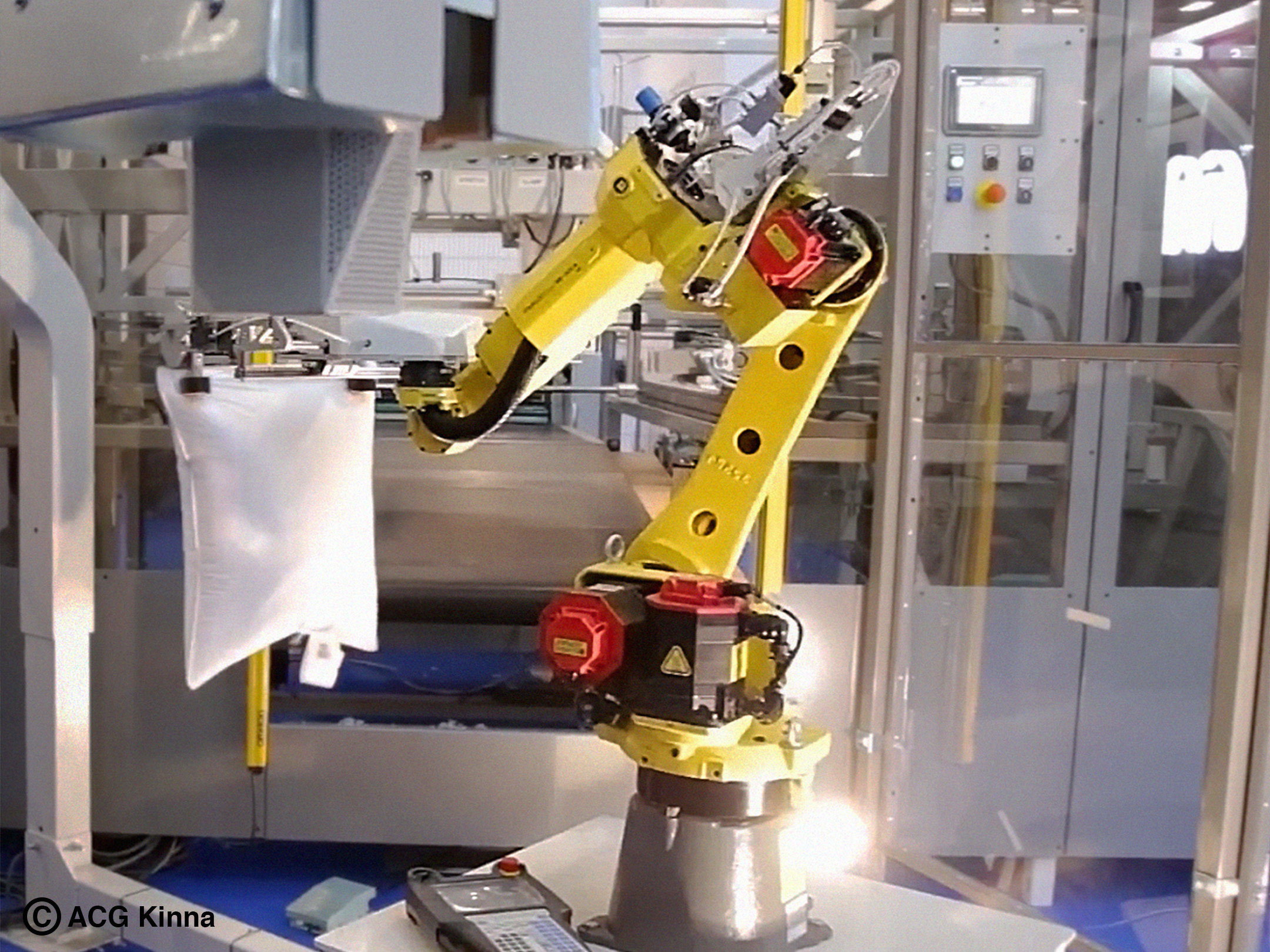

Since they generally involve fewer components and completion steps than garments, the fully automatic production of home textile products such as pillows, quilts and bags is more realistic, and a pioneer in this field has been Swedish company ACG Kinna with its robotic pillow filling system.

With the ability to fill and finish some 3,840 pillows per eight-hour shift, automated units cover the entire process – from the opening and weighing of the fibre to the filling of the product and on to the sewing and packing processes. Recently introduced features to this system include an integrated marking solution which allows QR codes, batch numbers and dates to be printed on the pillows’ labels.

A second Swedish company, Automatex, has meanwhile developed a sewing and assembly unit for the fully finished production of consumer bags, configured to carry out the automated hemming, handle insertion, cutting, labelling, bag forming and gusset forming which all previously had to be carried out manually. This automated system can to produce some 540 units an hour.

Ambitious goal

Despite such developments, the sewing process certainly remains the major bottleneck in almost every garment supply chain, making the development of a fully robotic sewing machine the ultimate achievement for the industry.

Another barrier of course, is that with 200 billion t-shirts currently produced every year, largely in developing countries, where labour cost is simply too low.

Electric sewing machines have served the fashion industry for more than a century and with many Industry 4.0-enabled quality enhancing and time-saving features, and visitors will be able to see some of these cutting-edge developments showcased at ITMA ASIA + CITME in Singapore.