28 - 31 October 2025 | Singapore Expo

Blog

Discover trending topics that are propelling the industry

All the tech for a US$2.1 trillion global textile market

The global textile supply chain powers markets that will generate US$2.1 trillion in global trade in 2026, according to forecasts from Swiss consultancy Gherzi.

This trade is not just limited to retail apparel – in itself a US$1.6 trillion business – but also consists of the US$300 billion market for home textiles and the US$230 billion that will be generated by technical textiles, including nonwovens and reinforcements for composites, in 2026.

Technology for every stage of the complex and highly globalised production stages contributing to these huge markets can be found at ITMA ASIA + CITME in Singapore from 28 to 31 October.

Extrusion and spinning

It all starts with the production of fibres, with some 125 million tons to be consumed next year, consisting of 61 million tons of filament, 50.4 million tons of short staple and 8.6 million tons of long staple fibres.

Polyester is by far now the widest used fibre globally, followed by cotton and to a lesser degree polyamide, polypropylene and wood-based cellulosic fibres such as lyocell. Other natural fibres such as wool and silk have their own highly specialised and well developed markets, as do aramid and carbon fibres for high performance applications.

From the total 125 million tons of fibres produced in 2026, approximately 112 million tons will be converted into yarns indicating that significant stocks are already held by the fabric producers.

Extrusion technologies for filament production will be showcased in Halls 3 and 4 at the Singapore Expo, alongside opening and blending and carding equipment for staple fibres. All three key yarn spinning technologies – ring, open end and airjet – will be comprehensively represented, as will the latest advanced winding systems. Fibre and fabric testing technologies and process control aids for this sector will also be displayed in Halls 3 and 4.

Textile surfaces

Of the 133 million textile surfaces produced in 2026, 77 million tons will be converted into fabrics by the traditional weaving and knitting routes, with a further 24 million tons of technical textiles produced either by knitting, weaving or braiding. A further 25 million tons of nonwovens – which omit the yarn stage in processing – will be manufactured, alongside seven million tons of materials for reinforcing composites.

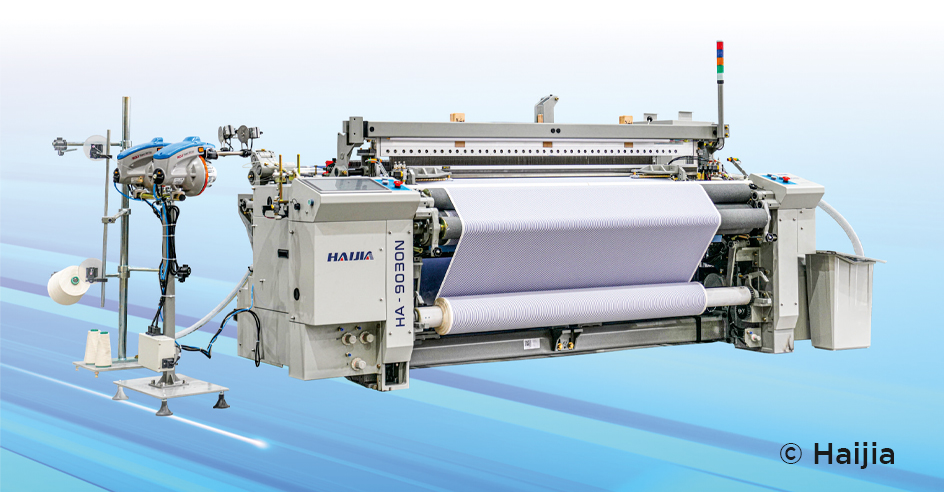

Weaving and braiding machines and staple fibre nonwovens processing equipment will be comprehensively represented in Hall 2 while Hall 5 is dedicated to knitting and embroidery.

Automation

There is of course, much more to do after the production of basic textiles on the journey to becoming final products for the retail shelves or specific industrial end-use markets. A wide range of technologies for their dyeing and finishing and conversion into finished garments or products will be on show across Halls 6, 7 and 8.

Illustrating the twin themes of digitalisation and sustainability, many exhibitors will demonstrate the latest digital printing systems that are now powering e-commerce, while a fast-growing area is the technology for the recycling of fibres and textiles, especially in respect of automated sorting and preparation.

ITMA ASIA + CITME, Singapore 2025 has now attracted over 800 technology and service providers from 30 countries and regions, and in response, show owners CEMATEX, CTMA and CCPIT TEX have expanded space to 70,000 square metres in order to accommodate them all.

“We are grateful to have the continued support of the industry and look forward to presenting all of the latest solutions for successful textile manufacturing to the region’s buyers seeking to leverage technology to drive cost efficiency and remain competitive,” says CEMATEX president Alex Zucchi.